Electric Chain Hoists

DC-Com chain hoist

The benefits at a glance:

Good value for money

- NEW Even better value thanks to twice the service life

- NEW Even better value thanks to 50% higher duty factor

- Fast availability

- Preferred models available direct ex stock

Reliable performance

- Various sizes with load capacities up to 2,000 kg

- Standard 4-m hook path

- 24 V contactor control

- Elapsed operating time counter

- Two lifting speeds

- High duty factor of 60% (40%/20%) for all load capacities

- Reliable operation from -20 °C to +45 °C without any reduction in the duty factor

High safety and reliability

- Slipping clutch with automatic cut-out by means of speed monitoring

- No load dropping, since the brake is arranged in front of the slipping clutch in the load-bearing arrangement

- High-quality powder-coated surfaces ?for improved protection and a longer service life

- IP 55 enclosure for chain hoist and trolley

Simple commissioning and operation

- Fast and simple commissioning ?thanks to plug connections

- The length of the control cable can be adjusted without the need for any wiring – the control pendant is always in the right working position

- Ergonomic handling

- Fatigue-free operation thanks to the ergonomically optimised DSC and DSE 10-C control pendants for electric-travel trolleys

- Single-fall design for simple load handling (for units up to 1,000 kg)

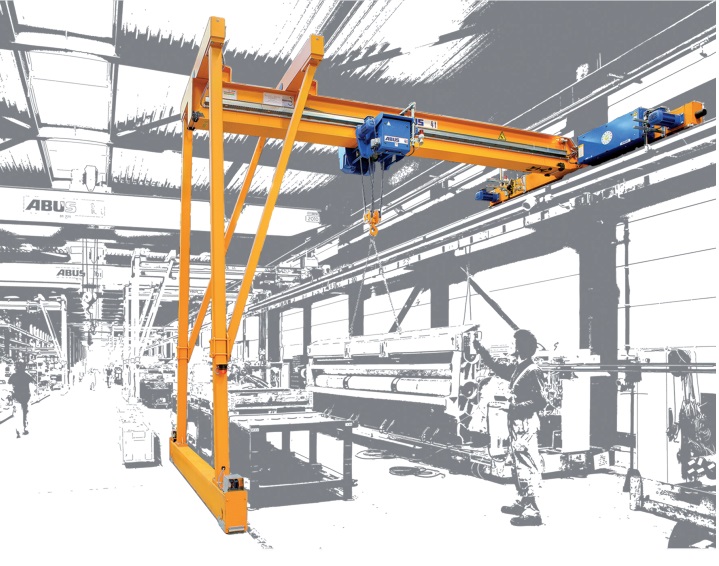

Trolleys and electric drives

- Push or electric travel in three sizes

- Fast and simple installation

- Infinitely variable flange width adjustment with adjusting rings

- Can be used on parallel and sloping flanges

- Integrated drop stop

- Smooth travel and low travel resistance

- Smooth starting and acceleration

Very easy to service

- Diagnosis interface

- Low maintenance requirement

DC-Pro chain hoist

The benefits at a glance:

High-performance equipment

- "All inclusive" features already as standard

- Two lifting speeds as standard

- 24 V contactor control

- Operating limit switches (upper/lower)

- Elapsed operating time counter

- Aluminium housing components with powder coating

- Duty factor: 60% (40/20), 360 starts/hour

- Signals for applications with three motion axes

- Suitable for tandem operation

- Comprehensive selection of finely graded load capacities up to 5,000 kg

- Two suspension brackets for improved C dimension (for sizes DC 1–10)

Long service life

- Gearbox, brake and slipping clutch are maintenance-free for up to 10 years (DC-Pro 10–25 brake for up to 5 years)

- Low-wear brake thanks to regenerative braking

- Brake adjustment is not necessary

- No load dropping thanks to slipping clutch arranged in front of the brake in the load-bearing arrangement

- Reduced chain wear thanks to 1/1 reeving for loads up to 1,000 kg

- Robust cylindrical-rotor motor with fan and separate DC brake

- No brake bonding thanks to double encapsulated brake

High operating reliability

- Standard requirements satisfied for functional safety

- No continuous slipping thanks to slipping clutch with automatic cut-out

- 24 V contactor control with internal “tri-state” signal transfer

- Chain hoist and travel drive feature IP 55 enclosure, insulation class F

- Automatic braking if the control system fails

Optimum egonomics

- Height-adjustable DSC/DSC-S control pendants with low-fatigue actuation force

- Control cable length and control pendant position can be adjusted to meet specific needs on site

- (without any need for wiring)

- Pivoting suspension bracket enables the chain hoist to be attached when the trolley has been fitted

Service-friendly

- "Plug & Lift" and "Plug & Drive" for all electrical connections

- Elapsed operating time counter, status and error messages shown on display

- Infrared diagnostic interface with IDAPSY software (to read out and manage specific data)

- Service cover for rapid access to plug connections, strain relief arrangements, collector for 3 m control cable and chain drive

- Chain lubrication through lubrication opening in the chain guide for improved lubrication between links (sizes DC 1–10)

- Reduced downtimes as chain drive can be replaced without dismantling motor or gearbox parts

DCM-Pro Manulift

The benefits at a glance:

Maximum ease of operation

- Infinitely variable speed control for lifting and lowering motions over the entire load range

- Exceptionally fine control at slow speed

- Smooth starting and exact positioning

- Creep lifting speed from 0.15 m/min

- Lifting speed, acceleration and braking ramp can be simply modified via the control unit

- Suitable for right-hand and left-hand operation

Versatile performance

- The various Manulift load handling attachments can be changed with ease

- Pro-Hub function for up to 90 per cent higher nominal speed for partial load or no-load operations

- Automatic switchover to creep lifting speed before the upper/lower limit positions are reached – speed ratio 1:100

High safety and reliability

- Motor temperature monitoring device

- Acceleration and braking ramps to reduce load sway

DCMS-Pro Manulift

The benefits at a glance:

Maximum ease of operation

- Infinitely variable speed control for lifting and lowering motions over the entire load range

- Exceptionally fine control at slow speed

- Smooth starting and exact positioning

- Creep lifting speed from 0.15 m/min

- Lifting speed, acceleration and braking ramp can be simply modified via the control unit

- Suitable for right-hand and left-hand operation

Versatile performance

- The various Manulift load handling attachments can be changed with ease

- Pro-Hub function for up to 90 per cent higher nominal speed for partial load or no-load operations

- Automatic switchover to creep lifting speed before the upper/lower limit positions are reached – speed ratio 1:100

High safety and reliability

- Motor temperature monitoring device

- Acceleration and braking ramps to reduce load sway