Travelling cranes

EKKE single-girder overhead travelling cranes

The benefits at a glance:

High stability and design rigidity

- Torsionally rigid, enclosed box-section profile with reinforced connection (welded diaphragm plates)

- Engineering tolerances in the crane girder connection area

- End carriages of torsionally rigid, welded box-section design

- Favourable travel characteristics and minimum wear thanks to low-maintenance drives

- Travel wheels of highly wear-resistant GGG 70 spheroidal-graphite cast iron with self-lubricating properties

- Optomum travel characteristics with minimum wear of crane runway and travel wheels

Highly cost-effective

- Low deadweight reduces investment layout – crane girders made of computer-optimised box sections

- Increased efficiency thanks to rope hoist with extended service life due to Demag 2m+ classification (1,900 hours of service at full load)

- Reliable monitoring and preventive maintenance thanks to CAN Bus technology to meet tomorrow's demands for high data transmission reliability (category 3 to DIN/EN 954)

- Optimum utilisation of the available height and space thanks to compact travelling hoist design and large hook path

- Reduced construction and operating costs thanks to optimised designs

Efficiency and performance

- Minimum wear of crane runway and travel wheels thanks to low-maintenance drives

- Control pendant suspended for separate travel on the crane girder with display for installation monitoring

- Power supply to the crab by means of highly flexible flat cable with protective earth conductor

- Optional radio control with power and signal transmission via energy chain system

- Optional radio control with display and proportional pushbuttons

EPKE single-girder overhead travelling cranes

The benefits at a glance:

High efficiency

- Reduced construction and operating costs thanks to optimised designs

- Travel wheels of highly wear-resistant GGG 70 spheroidal-graphite cast iron with self-lubricating properties

- Favourable travel characteristics and minimum wear of the crane runway and travel wheels thanks to low-maintenance drives

- Crane components selected for a long service life guarantee high operating reliability

Consistent performance

- Rigid standard I-beam girders for optimum load distribution

- Compact travelling hoist design with minimum approach dimensions and large hook path facilitate optimum utilisation of the available height and space

- Control pendant suspended for separate travel on the crane girder with display for installation monitoring

- Efficient and fatigue-free load handling thanks to higher cross-travel speed and optimised ergonomic control pendant

- Low-sway travel motions for smooth handling and exact positioning of loads (included as standard when variable-speed cross-travel drives are supplied)

Individual configuration

- Optimum integration into existing and new buildings

- Control pendant suspended for separate travel on the crane girder with display for installation monitoring

- Radio control with display and proportional pushbuttons possible (optional)

- Optional radio control with power and signal transmission via energy chain system

- Power supply to the crab by means of highly flexible flat cable with protective earth conductor

EPKE-O – single-girder overhead travelling cranes

The benefits at a glance:

- EPKE-O both as complete cranes or as crane sets (which do not include a crane bridge)

- Excellent value as an alternative to cranes that have box-section girders

- Additional safety thanks to derailment guard fitted as standard

- High operating reliability thanks to components that have a long service life

- Safe, reliable and rugged control system, either with an intelligent CAN bus processor system or with contactor control

- Simple installation saves time on site thanks to prepared assemblies

ZKKE double-girder overhead travelling cranes

The benefits at a glance:

Highly cost-effective

- Low deadweight reduces investment layout – crane girders made of computer-optimised box sections

- Connections between the main girder and end carriages manufactured to mechanical engineering tolerances for minimum wear

- Increased efficiency thanks to DR rope hoist with extended service life due to Demag 2m+ classification (1,900 hours of service at full load)

- Favourable travel characteristics and minimum wear of the crane runway and travel wheels thanks to low-maintenance drives

- Travel wheels of highly wear-resistant GGG 70 spheroidal-graphite cast iron with self-lubricating properties

- Reduced construction and operating costs thanks to optimised designs

Strong performance

- Particularly high performance thanks to double-girder design for high long and cross-travel speeds

- Optimum utilisation of the available height and space thanks to compact travelling hoist design (minimum approach dimensions and large hook path)

- Particularly high lifting height, as the load hook can be raised between the two crane girders

- End carriages of torsionally rigid, welded box-section design

- Power supply to the crab by means of highly flexible flat cable with protective earth conductor

- Reliable monitoring and preventive maintenance thanks to CAN Bus technology to meet tomorrow's demands for high data transmission reliability (category 3 to DIN/EN 954)

- Control pendant suspended for separate travel on the crane girder with display for installation monitoring

Great versatility

- Optional maintenance platform and accessible crab – for even easier crane maintenance as well as fast and safe access to building interior fittings (lights, radiators, supply lines)

- Optional radio control with display and proportional pushbuttons

- Optional radio control with power and signal transmission via energy chain system

- Large number of fittings can be installed

- Cab control

Components for Process Cranes

MPW open winch units

The benefits at a glance:

Convenient operation

- Matching modular components

- Motor, brake and gearbox in a compact arrangement offering simple replacement

- Clear interfaces for ease of assembly and maintenance

Strong performance

- Multi-groove rope drums for rope-stabilised systems

- Load capacities: 5 – 235 t

- Classification: M3 – M8 FEM

- Lifting capacity: up to 360 kW

- Reeving arrangements: 4/2, 8/2, 12/2, 16/2, 20/2, 24/2

- Designed and equipped for transport

High operating reliability

- For transporting molten masses

- Rope drum brake

- Second hoist brake: disc or double-jaw design

- Safety brake (acting on the rope drum)

MPW open winch crabs

The benefits at a glance:

Engineering excellence

- Few connection interfaces (drum, gearbox, motor and brake form a unit)

- Crab frame of welded steel design

- Optimum weight and torsionally rigid design

- Travel wheels largely wear-free

- Proven travel unit design used in our crane end carriages

- Bolted crossbeam connection

- Modular design

Simple assembly, convenient maintenance

- Fully equipped

- Minimum assembly requirement

- Jig-built, accessible crab frame with foot rails and railing

Great flexibility

- Ability to combine sub-assemblies from different types

- Just-in-time delivery

- Simple shipping in a container

Reliable operation

- Detailed function check of all motors and components

- Elimination of unnecessary interface connections

KTL corner-bearing end carriages

The benefits at a glance:

Outstanding performance

- Travel wheels made of high-quality spheroidal-graphite cast iron for low operating noise

- High resistance to wear

- Design to DIN 5018 (H2B3 – H4B6)

- Buffer options (hydraulic buffers, cellular plastic buffers)

- Tandem end carriages with connecting elements

Individual solutions

- Drive option with one, two or four driven travel wheels

- Corner-bearing wheel sets with diameters from 250 to 630 mm

Convenient assembly

- Direct connection to the crane girder – with one or two machined connection surfaces depending on the design

- Simple, time-saving handling

- Simple maintenance and adjustment thanks to corner-bearing wheel sets that can be rolled out of the girder

- No additional components need to be removed

Low-maintenance drives

- No special tools required

- Compact, matching ZBA motors and AU gearboxes

- Direct splined-profile connection to the travel wheel shaft (easy to remove)

- Flexible torque-load connection to the end carriage thanks to elastic torque arm

- Low-noise operation thanks to ground helical gear wheels running in an oil bath

Pillar and wall-mounted slewing jibs

The benefits at a glance:

Comprehensive crane product range

- Finely graded jib lengths and load capacities for precisely implementing specific requirements

- Slewing range limit stops for exact adjustment of the working radius

- Large selection of Demag hoist units

- Control to meet specific needs: via cable connection or by radio

- Delivery including complete electrical equipment

- Weather protection accessories for cranes installed outdoors

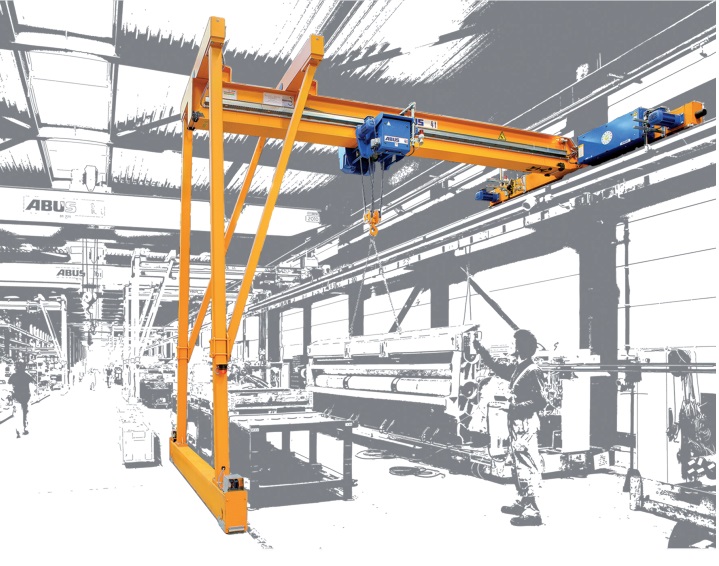

KBK portal cranes

The benefits at a glance:

Three variants

- EVP-KBK single-girder full-portal crane – KBK II or KBK II-H crane girder

- ZVP-KBK double-girder full-portal crane – KBK II or KBK II-H crane girders

- D-IVP single-girder full-portal crane – I-beam section crane girder (with optional telescopic height adjustment)

Practical applications

- Easy to manoeuvre

- Can be simply dismantled for transport

- Quickly re-erected at a new operating site